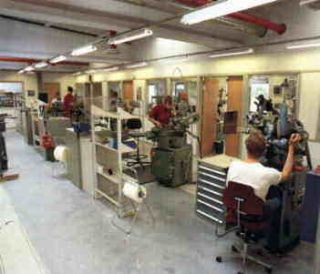

Machine Inventory

CNC grinding

CNC grinding machine, Walter Helitronic Power, with 5 axes and updated with the latest software. We can offer all types of grinding of cutting tools in carbide and HSS. The machine is equipped with robotic loader for small and larger batches.

CNC turning and milling

The CNC turning and milling group produces shaft materials for special steel profiles and form drills. Limited-run tools can be produced according to customer drawings.

Universal grinding

Our special machines are fitted with spiral attachments, radius device, digital display and measuring glass with 40 x enlargement ensuring that dimensions, radius and angles are measured directly during the manufacturing process. Production includes form drills, broaches, prickers, barrel bores and broaching tools in carbide and HSS as well as tools with soldered plates or changeable standard carbide inserts. All tools can be surface treated and coated by means of state-of-the-art coating processes.

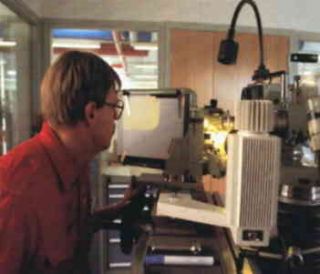

Profile grinding

Grinding of steel profiles with soldered plates and changeable inserts on special machines with projector screens. Measurement ratio 1:10, 1:20 and 1:25

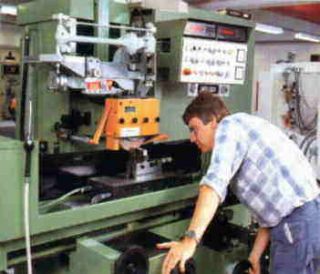

Surface grinding

Blohm surface grinder equipped for deep grinding with diaform 1:10 and digital measuring equipment.

Circular grinding

Circular grinding is performed on Studer machines with cyclic programme, measurement control and digital display. External and internal grinding of series runs from 1-100 pieces. Dimensions of up to 350 x 700 mm can be undertaken. Grinding with a tolerance of ± 0.001 mm can be performed.

Measurement area

All finished tools are tested/measured up in our measuring area prior to despatch. An inspection report can be supplied upon request.